Engineering Update - May 2015

Locomotive Frame Assembly

Work continues on a number of fronts on the construction of The Unknown Warrior.

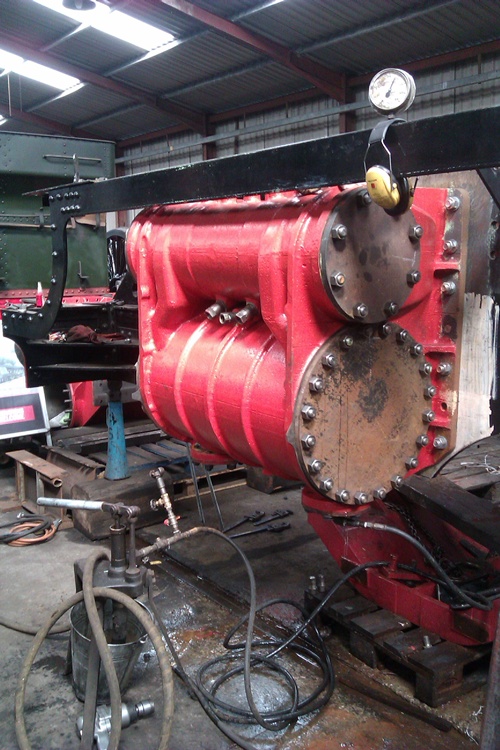

Following the fitment of the Cylinders work continued toward conducting hydraulic testing of the cylinder blocks. This showed up a few minor porous sections in the castings, where, whilst under high pressure small beading of water like sweat appears on the casting surface. The castings have now been sent away for specialist treatment to seal these sections They are due back at Llangollen in the next few days to be re-fitted to the frame assembly.

The LH cylinder under hydraulic test at Llangollen shed. 23rd April 2015 The pressure gauge is reading 250psi.

Photo – Kevin West

Other work continues on the Frame Assembly as time and work force availability permits. Unfortunately since the last report the Arwell and Chris have been called on to work on the Llangollen Railway home fleet locos, so progress is not as great as we would have expected. Discussions with Llangollen Railway have been held to see if this can be addressed in the future.

The volunteer painting gang continues work on the locomotive frames and Driving Wheels. Work has also started on refurbishment of the legacy motion parts acquired from Jubilee class locomotives a couple of years ago.

Drawings have been sent out for quotations for the four leading Sandboxes.

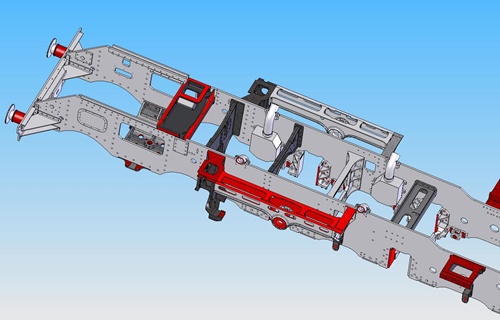

CAD image of the Sandboxes fitted inside the Frame Assembly.

Photo – Kevin West

Design work is continuing on the remaining Valve Gear parts required.

Brake System and Lubrication System

The locomotive Brake Cylinder from 8F 48518 has been moved to Harco Engineering for refurbishment. This move was due to happen some time ago, It had been placed in safe storage – so safe no one could remember where! It finally can to light in a van under parts for another loco being re-assembled at LLangollen.

On the Frame Assembly the Brake Hanger Brackets have been riveted to the Frames.

Brake Hanger Bracket

Photo – Kevin West

The Brake Hangers are due to be cast about now.

Brake Hanger pattern

Photo – Premier Patterns

Work is also underway on the design of the lubrication system. The Lubricators themselves are under overhaul, one at the Great Central Railway, Loughborough and the other will be done at Llangollen.

The installation of all the copper pipe runs is a huge undertaking which we are to start progressing this summer. We have the offer of a volunteer who wishes to work on the locomotive for a few weeks this summer. If anyone wishes to help on this work, even for a few days please contact the project office. Your help will be greatly appreciated.

Pistons, Valves and Motion

Work continues at Llangollen towards fitting the Motion Girders to the Frame Assembly.

Once the Cylinder are in place fitting the rear covers and slide bars will progress to completion

The Piston casting will be ordered soon.

Manufacture of the Coupling Rod Bushes and Brasses is expected to start soon at Llangollen.

The End Strap for the Inside Connecting Rod was forged at Sommers Forge on 6th May. The steel arrives as a square billet. This is placed in a furnace and heated to 1200 degrees C for 8 hours before being placed under the forge hammer and worked into a flat piece ready for profiling and subsequent machining.

The billet being moved from the furnace to the forge hammer.

The End Strap takes shape.

Photos – Kevin West

Bogie

Work on assembling the bogie has commenced at Tyseley Locomotives Works. A small amount of remedial work has been required on the Bogie Centre casting, which id due for completion next week. Next stage will be to mount the Frame Plates to the Centre Casting.

Horn Guides being fitted to the Bogie Frame Plates.

Photo – Kevin West

Detail discussions with our Vehicle Acceptance Body (VAB) and South Devon Engineering over the assembly of the new Bogie Wheelset, to ensure it complies with the new RISAS standards have reached an acceptable conclusion. .Drawings have been updated in line and passed to Harco Engineering to allow the Axle and WheelCenters to be machined.

Boiler

Work continues on the forming blocks for the outer firebox Steel Flanged plates at Tyseley Locomotive Works.

At LNWR Crewe, the Inner Firebox components are now in the new works at Crewe South, ready for assembly to start..

The new drawings required for the design changes to the boiler submitted to the insurance company for their approval have all been passed.

The barrel section rolled at Deepdale have been delivered to Crewe. Work is in progress on the Foundation ring with material acquired ahead of manufacture. The steel Outer Firebox Wrapper sheet is about to be ordered from Deepdale. This is formed from 3 sheets of material and agreement on the positions of the 2 welded joints has been agreed to allow manufacture to commence.

Tender

Work on the refurbishment on the Tender Frames continues at Rowlescourt Engineering. The Tender Frames were inspected by a representative of our VAB, who recommended wjich parts of the Rear Drag Box required replacement. As the work required to remove the plates would involve removing virtually all the Drag Box it has been decided to replace the complete assembly with a totally new fabricated unit. The VAB have been informed and agreed to this approach.

Following on from this, cad data and drawings for the required steel parts were prepared and passed to Rowlescourt to allow construction to continue.

Work in progress on the Tender Dragbox Assembly.

Photo – Kevin West

The Front Drag Box will follow the same route. Cad work for this is underway.

The design for the new tender tank has been progressing when time allows.