Engineering update - December 2015

Locomotive Frame Assembly

Work continues on the construction of The Unknown Warrior at number of locations. The construction of a steam locomotive of any size is a complicated engineering task and the past few weeks have proved to be just that. While it may appear that not a lot is happening above the surface, in fact the 8 legged duck is paddling furiously although perhaps not all in the same direction!

The Unknown Warrior on display at Tyseley Locomotive Works, 24th October. Photo – Kevin West

Following the locomotives arrival at Tyseley work has not progressed at the pace we had expected due to a number of reasons. The major reason has been the discovery that the Cylinder & Valve Liner castings all required replacement due to having voids and blow holes in the castings. This was not discovered until the castings had been part machined. Replacement castings have now been produced and proof machined by the foundry and are due to be moved for final machining this week. Once the machining has been completed they will be moved to Tyseley for shrink fitting into the Cylinders.

In preparation for the liner machining detailed measurements of the cylinders were taken to establish the require diameters required to ensure the correct fit into the cylinder castings.

The fitting involves the liner being immersed into a tank of liquid nitrogen which make the liner shrink slightly so they can be inserted into location in the Cylinder. As the liners warm up and expand to normal size they become a slight interference fit in the cylinder casting which holds them in position. A number of set screws provide a final location. The interference required on our cylinder liners of 19 3/16” outside diameter is only 3 thousands of an inch.

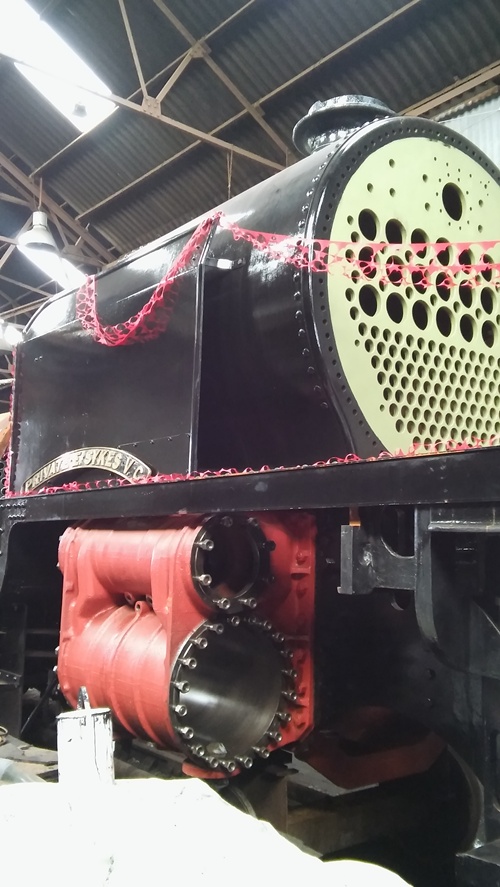

Left Hand Cylinder with Covers and Slide Bars removed in preparation for the liners to be fitted. Photo – Kevin West

The 155 drawings obtained from the National Railway Museum, York and Glasgow University have been catalogued and filed for easy access when required.

Back at Llangollen parts continue to arrive for fitting when the locomotive returns. These include the Guard Irons.

Guards Irons at Llangollen. Photo – Jordan Leeds

The Sandbox Necks have been machined at Harco and will be sent to Llangollen for fitting to the frame when it returns to Llangollen.

Brake System and Lubrication System

Refurbishment of the Locomotive & Tender Brake Cylinders from 8F 48518 continues at Harco Engineering.

Design work continues for the lubrication system. A replacement body and new lid castings for the Mechanical Lubricator under overhaul at the Great Central Railway, Loughborough have been produced and delivered to Loughborough.

Lubricator Body casting– Photo:- Kevin West

Lubricator Lid casting– Photo:- Premier Patterns

Design work for the lubrication pipework runs, fittings and clips continues.

The Brake Hangers have been moved to Llangollen Engineering for machining which is due to be completed this week. Drawings for the associated Pins, Nuts etc have been finished and quotation to manufacture have been sent out for quotations.

Pistons, Valves and Motion

As detailed at the beginning of this report the castings obtained for the cylinder and valve liners had to be rejected due to casting faults. New castings have now been produced using a modified casting method and a sample have been proof machined with encouraging results. We expect the castings to be delivered for final machining this week.

Castings for the Pistons have been cast and will be delivered to Tyseley soon. An order for Tyseley to supply completed Piston and Valve assemblies has been raised. These include finished Pistons, Piston Rings and Piston Rods and Valve Heads, Rings and Rods.

Drawings for the Gland and Stuffing Box parts for the Piston Rods and Valve Rods are in progress to enable manufacture.

Llangollen Railway Engineering are also progressing the manufacture of the Coupling Rod Bushes and Brasses.

Machining the cast Expansion Links is underway.

One of the Expansion Links undergoing machining. Photo – CMS Cepcor Ltd

The Inside Connecting Rod assembly has made a major step forward with the machining of the Big End Strap by CMS Cepcor in Coalville. To ensure the correct fit to the Inside Connection Rod, the Rod itself was moved to CMS in early mid December. It was set up on a large milling machine to measure the mating faces which were given a light skim to remove some slight pitting which had occurred since the rod had been removed from Jubilee 45697 Achilles in 1967.

Big End Strap undergoing machining. Photo – Kevin West

Inside Connecting Rod undergoing machining. Photo – Kevin West

Big End Strap finished. Photo – Oakwood Visuals

Drawings for the pins, nuts and other parts required for the Big End assembly have been finished and delivered to CMS Cepcor to manufacture.

Castings for the Big End Bearings have also been procured. Quotations for machining to finish are being obtained.

Big End Bearing casting. Photo – Premier Patterns

A number of parts for the motion have also been acquired over the last few weeks. The inside valve gear Eccentric halves have been cast and delivered to Harco for machining. Also at Harco are the Reversing Shaft Trunnion castings and bearings. The Inside Crosshead has also been cast and now awaits machining. Also cast are the Outside Valve Crosshead Brackets.

Eccentric castings. Photo – Kevin West

A selection of castings at Premier Patterns Valve Crosshead Bracket, Sandbox Lids,Reverser Shaft Trunnions, Lubricator Body and Inside Crosshead. Photo – Kevin West

Crosshead casting. Photo – Kevin West

The Cylinder Relief Valve Body castings have also been ordered. Once they are to hand they will be sent for machining. The castings for the valve spring holders are also on order. The valves will be ordered soon.

Bogie

The Bogie Wheelsets have finally had their tyres profiled fitted at the London Midland depot at Tyseley just before Christmas after a delay in finding time on the lathe. The local DMU fleet had experienced a number of wheel flats over the late autumn and obviously took precedent over our wheelsets.

The Bogie Wheelset after tyre turning. Photo – Kevin West

Assembly of the bogie is nearing completion at Tyseley Locomotives Works. The bogie frame is now complete with Side Control Springs and Beams in place. Some remedial machining was required on the Bogie Centre Pin casting and the fitted bolts to fit this and the Bolster Plates to the locomotive chassis are on order.

The Bogie Frame under assembly at Tyseley. Photo – David Bradshaw

The Axleboxes for the new wheelset have been white-metaled and machined ready for fitting.

Boiler

Preparation work continues at Tyseley Locomotive Works for the forming of the Outer Firebox Steel Flanged plates.

The Outer Firebox Wrapper sheets were formed at Deepdale Engineering in early January 2016. The three sheets were then prepared for welding before delivery to LNWR Heritage, Crewe.

Outer Firebox Wrapper sheets during forming at Deepdale Engineering. Photo – Oakwood Visuals

The welding was completed on 14th January.

Outer Firebox Wrapper sheets after welding at Deepdale Engineering. Photo – Bob Sweet

At LNWR Crewe, the Inner Firebox Crown and side sheets are expected to be welded in the next couple of weeks. The assembly of the Inner Firebox is due to start at the beginning of February.

The 2 barrel rings are ready to be riveted together when there is capacity in the works. The Foundation Ring components are ready to be sent away for machining before welding in the side sections.

LNWR Heritage have agreed the completed boiler will be ready for delivery in January 2017.

Tender

Work on the refurbishment on the Tender Frames continues at Rowlescourt Engineering.

Final machining of the new welded dragboxes for both front and back has been completed and they are installed in the frame assembly.

Rowlescourt had intended to complete the chassis repair by the end of the year, to allow the chassis to be returned to Llangollen for the Drag Boxes and outer flanges to be riveted in place. Due to an influx of commercial work in late November and December we now expect the Tender Frame to return to Llangollen around the end of January

Design work on the new tank which will be of welded construction with dummy rivets is continuing taking into consideration the requirements for new main line running regulations.

Future work planning

Following fitting of the Cylinder & Valve Liners and the Bogie assembly at Tyseley Locomotive Works, the locomotive will return to Llangollen. This is now expected to take place in February.

Once back at Llangollen work will continue on setting up the Inner Slidebars.

A start will also be made on the lubrication pipework.