Reduced to £5.00 plus £2.50 p&p

Engineering Update - April 2017

Locomotive Frame Assembly

Work continues on the construction of The Unknown Warrior at number of locations.

This report starts with the good news that Chris Collins has returned to work at Llangollen following his medical issue earlier in the year.

A different view of the Unknown Warrior inside the shed at Llangollen. March 2017.. Photo – Kevin West

Work has continued on a number of fronts at Llangollen in the last month.

The Crank Axle has been reinstalled in the chassis following its return from the South Devon Railway where the Inside Eccentric was fitted.

The Crank Axle Assy with the Eccentric fitted outside the shed at Llangollen. March 2017.. Photo – Kevin West

Close up views of the Eccentric. March 2017.. Photo – Kevin West

Following the fitting of the Outside Valve Crosshead Brackets, measurements have been taken to enable the dimensions of the Valve Crosshead Slides to be established. The drawings have been finalized and the parts are now on order.

Front Outside Slidebar Fixings showing the bolts and castellated nuts. Photo – Kevin West

The Slide Bars are fitted permanently and the Oil Pot mounting holes have been drilled and tapped. Drawings have been prepared for the Oil Pots which are based on those fitted to 45596 Bahamas.

Oil Pot as mounted on 45596 Bahamas. Photo – Kevin West

Rear Outside Slidebar Bracket showing the fixing bolts and oil pot mounting. Photo – Kevin West

Other parts for the chassis recently delivered to Llangollen include the Trailing Sandboxes, which will be fitted to the Platforms alongside the Firebox. It is anticipated these will be fitted in the next couple of weeks.

All the Sanding Gear Brackets and Mounting Plates are at Llangollen being painted ahead of being fitted to the Chassis.

The Cylinders cladding sheets have been ordered and are due for delivery to Llangollen, where the mounting holes in the Cylinders will be drilled and tapped.

The three Drawbar forgings have been delivered to Llangollen. They will need machining at some time in the future before fitting.

The three Drawbar forgings. Photo – Kevin West

Brake System and Lubrication System

The major activity on the locomotive recently has been the fitting of the Brake Gear. The Brake Hangers have had grease lubrication nipples fitted by the machine shop prior to mounting into the Hanger Brackets.

The Brake Hangers prior to being installed. Photo – Kevin West

The gear was completed with the Cross Beams and Pull Rods for all the Driving Wheels.

One of the Brake Hangers installed. Photo – Kevin West

Left side Middle and Trailing Driving Wheels showing the Brake Hangers, Cross Beams, Bridle and Pull Rod. Photo – Kevin West

A close up view of the Middle Cross Beam, Bridle and Pull Rod. Photo – Kevin West

A close up view of the Brake Gear for the Middle and Rear Driving Wheels during assembly. Photo – Kevin West

The new 10 1/2” Brake Cylinder is still awaited at Llangollen following delays at the supplier. Once delivered it will be installed under the Drag Box below the Cab.

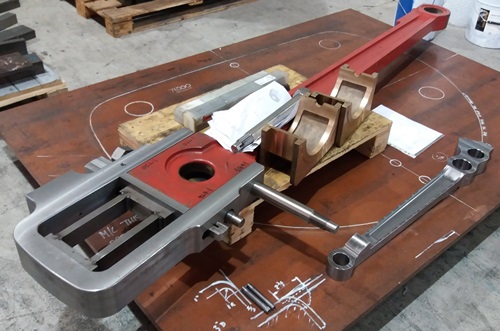

The Brake Cross Shaft Mounting Brackets were delivered to Llangollen on 26th April. This structure will be riveted together and painted before mounting in front of the Brake Cylinder under the Drag Box.

The Brake Cross Shaft Bracket structure following delivery to Llangollen and being loosely assembled. Photo – Kevin West

A view from above the Chassis showing the Leading Cross Beam ahead of the Crank Axle. Photo – Kevin West

The Brake Gear assembly shown from underneath the Cab. The Brake Cylinder and Cross Shaft Bracket will be mounted at the top of this picture under the Drag Box with the Trailing Pull Rod connected to the pin that can be seen this side of the Cross Beam. Photo – Kevin West

Following approval that the Brake Cross Shaft can be fabricated instead of the original forging, the drawings have been sent out for quotation and specification for the welding to be agreed. It is expected the order will be placed in the next couple of weeks.

All the Driving Wheel Springs are now being fitted, with those for the Crank Axle being the last to be installed.

The right hand trailing Spring in position. Photo – Kevin West

A start has been made on the manufacture and installation of the Lubrication pipework.

The first of the Lubrication Pipework being installed. These are for lubricating the Trailing Horn Guide Slides. Photo – Kevin West

The 8 feed mechanical Lubricator has been collected from the Great Central Railway at Loughborough where it has been overhauled. Along with the larger 16 feed unit these are now ready to fit to the Locomotive when required.

The 8 feed mechanical Lubricator. Photo – Kevin West

A start has been made on installing the fittings required on the Lubrication system. These include the Non Return Valves on the Cylinders and the pipe bulkhead fittings on the rear of the Inside Cylinder.

The non-return valves installed in the Valve chest of the right cylinder and the bulkhead fittings being installed on the rear face of the Inside Cylinder. Photo – Kevin West

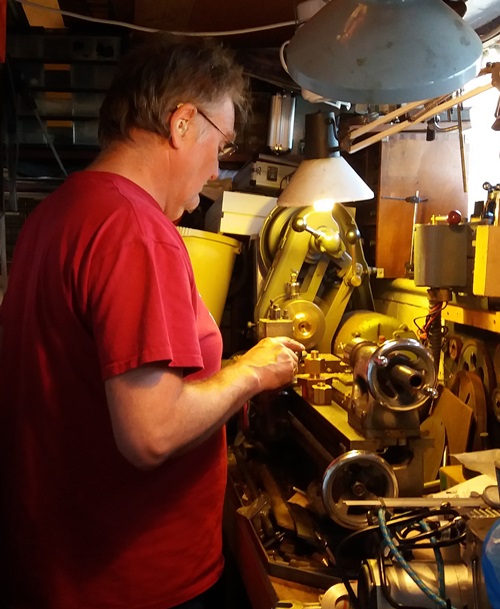

Two of the pipe bulkhead fittings required the body diameter to be reduced slightly to fit into the cast holes in the rear bulkhead of the Inside Cylinder. This gave the Chief Engineer the excuse he needed to clear out the clutter from his workshop and machine the fittings as required over the Easter break.

A Bulkhead fitting in the lathe ready for machining. Photo – Kevin West

The Chief Engineer machining the Bulkhead fitting. Photo – Joanne Baddock

Refurbishment of the original 9” Tender Brake Cylinder from 8F 48518 continues at Harco Engineering.

Pistons, Valves and Motion

Work is progressing on the procurement and manufacture of the remaining Inside Valve Gear parts.

Llangollen Engineering continue on the manufacture of the Coupling Rod and Connecting Rod Brasses and Bearings. Once the Bearings are finished they will be pressed into the Rods ready for trial fitting to the Locomotive.

The Connecting Rods, Coupling Rods and Outside Eccentric Rods at Llangollen. Photo – Kevin West

Inside Eccentric Rod in the machine shop at Llangollen with fitting to the Front Eccentric Sheaf. Photos – Kevin West

Work is almost complete on the parts for the Inside Connecting Rod Assembly at CMS Cepcor, ready to move to Llangollen. The Big End Brasses will be white metaled and machined at Llangollen on arrival.

Inside Connecting Rod assembly in the machine shop at CMS. Photo – Kevin West

Also at CMS, the new Inside Combination Lever is almost finished, only requiring the oil reservoirs and oil ways need finishing.

Inside Combination Lever almost finished at CMS. Only the oil reservoirs and oil ways need machining. Photo – Kevin West

Work has started on machining the new Inside Crosshead. Once finished it will move to Tyseley Locomotive Works for finishing and fitting to the Piston Rod.

Inside Crosshead showing first stages of machining at CMS. Photo – Kevin West

Work continues on the manufacture of the remaining Motion parts we have on order, including Union Links, Main and Intermediate Reverser Shafts, Return Cranks, Valve Crossheads and the Cab Reverser

Assembly.

The castings for the main Reverser Shaft Balance Arms. Photo – Kevin West

Flame Cut Blanks for the Union Links and Inside Drop Link at CMS. 2 of the Union Links are for The Unknown Warrior, the third is for Jubilee 45596 Bahamas. Photo – Kevin West

Work continues on the final design of the Piston Rods and Valve Rods.

The Inside Radius Rod drawings have been completed and sent out for quotation. This is the final motion part required for the locomotive.

Manufacture of the many pins, nuts, bushes etc for the motion continues.

A selection of recently completed fittings for the motion work. Photo – Kevin West

Drain Cock Gear, Cylinder Relief Valves & Sanding Gear

The Brackets and associated mountings for the Sanding Gear are being painted prior to fitting to the Locomotive chassis.

The Sanding Gear Brackets and Plates in grey undercoat along with the Trailing Brake Pull Rods and a Driving Wheel Spring. Photo – Kevin West

The Trailing Sandboxes have been delivered to Llangollen and are being painted before mounting on the locomotive.

The Trailing Sandboxes. Photo – Kevin West

The Trailing Sandboxes being painted in primer at Llangollen. Photo – Kevin West

Boiler

Construction of the Boiler is now concentrated at LNWR Heritage, Crewe following delivery of the Throatplate components.

The two major parts of the Throatplate laid out at LNWR, Crewe. These parts are joined by rolled sections of plate which are welded into the gaps. Photo – Gavin Shell

The assembly of the copper Inner Firebox is also continuing in preparation for final riveting.

The Inner Firebox. Photo – Gavin Shell

The Dome and Dome Cover castings wait delivery to CMS for machining. Photo – Kevin West

The project has recently been donated the regulator handle from Jubilee class 45552 Silver Jubilee by member Tony Digby. At present we are unsure if it is possible to use this on The Unknown Warrior, but investigations will be undertaken shortly. It will be interesting to see if this can be used as it comes from then next loco number from The Unknown Warrior. Also the first batch of 10 Jubilees were originally ordered as Patriots. Tony also donated an LNWR Gauge Glass Lamp.

The Regulator Handle from Jubilee 5552 Silver Jubilee. Photo – Kevin West

The number 5552 stamped into the regulator handle. Photo – Kevin West

LNWR Gauge Glass Lamp. Photo – Kevin West

Tender

Work on the refurbishment on the Tender Frames has made considerable progress over the last couple of months as we have had two engineers working on it full time.

The new Main Frame Plates have been positioned and drilled ready for final riveting of the chassis assembly. The new Rear Beam plate is awaited delivery from the supplier. It will be drilled on arrival at Llangollen.

The Tender Chassis being set up. Photo – Kevin West

The Front Beam, drilled and in position ready for riveting. Photo – Kevin West

Closer view showing the Main Frame plate drilled and in position. Photo – Kevin West

The Tender Axlebox Bearing Brass castings have been delivered. A drawing is required for machining. The Axleboxes will need measuring first to enable the correct fitting dimensions to be established.

The Tender Axlebox Bearing castings. Photo – Kevin West

The changes we have proposed to make to the Tender body have been accepted by our approvals body. This means we can now start to finalise the design work and prepare the required detail drawings. This will require some liaison with prospective suppliers to ensure the design of the plates meets the manufacturing requirements.

Future Work Planning

Areas of existing design work include, Boiler Cladding Sheets, Cab Footplate structure and Tender Tank.

The Project sales stand at the recent Strictly Bulleid event at Swanage. Photo – Kevin West

All this work requires large levels of expenditure on part manufacture and fitting, so the work of our sales team in spreading the word at events up and down the country is vital to the continued progress. As well as manning the stand at events these are also very sociable events and new volunteers are welcome to join and help.

Gavin Shell and Kirsten Shell at Swanage. Photo – Kevin West

The Unknown Warrior, Llangollen 26th April 2017. Photo – Kevin West