Reduced to £5.00 plus £2.50 p&p

Engineering Up-date - May 2019

Submitted by alaws on 20 June, 2019 - 12:21

Since the last Engineering report review we finally gained access to the former Boiler Shop at Crewe Heritage Centre which enabled us to vacate the Main Hall area which we had occupied since arrival at Crewe back in October 2018. The actual moving date was 18th April 2019 just prior to the Easter Bank Holiday.

No sooner had we moved in, a phone call was received from the operators of 60163 'Tornado' who were required to carry out urgent repairs to some leaking stays on their boiler. This would necessitate the removal of the cab to gain access to complete the repairs. Tornado was at the time based at Crewe for an extended period to work on local charter trains. In order to facilitate this they needed access to the boiler shop. This was agreed and over the next week or so it was good to see two new-builds occupying the same workshop space.

60163 Tornado sharing shed space with 5551 The Unknown Warrior, at Crewe Heritage Centre. Photo – Steve Blackburn

The move into the workshop has allowed us to continue work unhindered and in a more

secure location. The agreement reached will allow us access until at least the end of July 2019.

5551 inside the workshops at Crewe Heritage Centre. Photo – Steve Blackburn

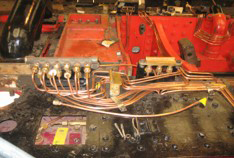

LUBRICATION

Work continues on the completion of the lubrication pipework under the supervision of LMS-Patriot Project Contractor, Nigel Day. This is a time consuming task but is vital to efficient running of the locomotive in future years. This work is expected to be completed by the end of June.

New Lubrication Pipework. Photo – Steve Blackburn

MOTION

Following removal and inspection of the motion it was agreed to source a new supplier to carry out the rectification work to the motion bearings. The work carried out by Llangollen Railway Engineering was not up to the required standard on such a safety critical component, so the situation had to be urgently addressed.

The new supplier is Statfold Barn Engineering and arrangements were made to transport the motion parts to their premises at Tamworth, this took place at the beginning of March. Once there a visit was arranged to agree the details of the work to be carried out and envisaged timescales. Work is progressing well with most tasks identified and a projected delivery back to Crewe for fitting of mid to late June 2019.

Following the removal of the centre driving wheel set for transportation to Multi-Tech Engineering (UK) Ltd. for rectification work to the crank pins, the centre driving axle boxes were removed and found to have been starved of lubrication, resulting in the white metal bearing faces showing signs of damage. This damage is not extensive and can be rectified but the front and training wheel sets will need to be removed for inspection and similarly treated if required.

It is the intention to lift the frames off the wheels within the Boiler Shop using hydraulic jacks. These are currently being sourced with a view to doing the lift before the end of May 2019.

During the first week of May, Andy Forster was commissioned to carry out alignment checks on all slide bar arrangements for all three cylinders. The checks included cylinder to frame and both vertical and horizontal alignments. The results are now being analysed to formulate corrective actions where required.

Following the two abortive attempts to manufacture a fit-for-purpose reversing shaft a revised design has been submitted to the Vehicle Acceptance Body for approval. This was duly given and tenders are currently being sought from new suppliers for the manufacture of the component.

When the lift is carried out to free the other two driving wheel sets the bogie will be removed to ensure that the lubrication of the two wheel sets is satisfactory and is not suffering the same problem as the centre driving wheel set.

OTHER WORK

Amongst the other tasks currently being undertaken, the pressure relief valves have been fitted to the two outside cylinders.

Pressure relief valves now fitted. Photo – Steve Blackburn

There is a problem with the front valve to be fitted to centre cylinder which may result in a design change to provide the necessary clearance above the front bogie. This is to be further investigated.

The exhaust steam manifold at the front of the locomotive has also been trial-fitted and some modification will be required.

Exhaust steam manifold. Photo – Steve Blackburn

THE NEXT STEPS

It is planned to get the chassis in as complete state as possible before being shipped to our preferred supplier to finish the build. The largest part of this work will be fitting the boiler. This will be done in conjunction with Heritage Boiler Steam Services (HBSS) who are currently working on the boiler at their workshops at Huyton near Liverpool.

There are still some parts of the design that need final approval from BES who are overseeing the manufacture of the boiler to meet legislative requirements.

HBSS will also be contracted to complete the boiler cladding. The manufacture and fitting of all the pipework between boiler, cab, smokebox, cylinders, valves and injectors will form large part of the work and will all be bespoke as no detailed drawings exist. Additionally various components are not as originally fitted such as the main steam injector is of Great Western design not LMS and the exhaust steam injector has been replaced with a second live steam injector.

Consideration is now also being given to the design input required for the fitting of main line electronic equipment required as part of the certification process. The manufacturer are currently being asked for their requirements to achieve this part of the build.

BOILER UPDATE BY ANDREW WILCOCK, Director, Heritage Boiler Steam Services Ltd.

5551’s boiler is progressing nicely. Since being trial-fitted in the frames last November the boiler returned to our Huyton workshop, where the main structure of the boiler has now been fully riveted. All side stays are currently in the process of being reamed and tapped and the first batch of copper stays have been ordered. Many components, such as internal brackets/clips, are currently being manufactured and all copper pipework is now in stock and will be manufactured in the coming weeks. Recently the dome was fully fitted and riveted on.

Photos – Heritage Boiler Steam Services

The next task is to look at the J pipe and regulator arrangement. The front tubeplate has been removed to aid access while this is carried out. All palm stays are finished and ready for fitting. Transverse stays are also on order and should be with us in the next few weeks.

Please visit the HBSS Facebook page for regular updates and more photos of work progress.

SUPPORT COACH UPDATE

The coach we have identified as a possible support coach for use with 5551 The Unknown Warrior is Mk1 BSK No. 35457 which is currently stored at the North Norfolk Railway. A survey was carried out by Geoff Armstrong of Wayne Jones and Partners with a few small issues being found, the main one being some water damage to the vehicle ceiling where the source of the leak needs to be identified. This is something we are told is fairly typical of Mk1 coaches.

The closing remark in the report is that we would struggle to find another Mk1 available for purchase in a better condition. Negotiations are currently taking place with the owner.