Engineering Update - October 2015

Locomotive Frame Assembly

Work continues on a number of fronts on the construction of The Unknown Warrior.

The Unknown Warrior takes a rest at Donnington Services during its movement from Barrow Hill to Tyseley, 29th September. Photo – Kevin West

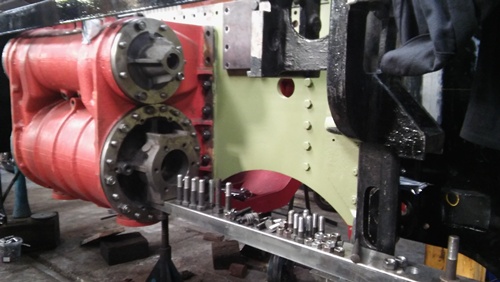

The major work of permanent fitting the cylinders and Motion Brackets to the locomotive has been completed.

All the Cylinder and Valve Cover were fitted temporarily along with the Outside Slide Bars, ready for the locomotives trip to Barrow Hill in mid September.

Left Hand Cylinder with Cover fitted and Slide Bars being worked on. Photo – Kevin West

The Motion Girders have also been temporarily bolted into position. They will be removed for some final machining of oilways once the locomotive returns from Tyseley. The high tensile bolts have been purchased to permanently fit the Girders as well. The platform above the Girders also requires to be riveted into place before the Girders are permanently mounted. This work is scheduled to be completed soon after the locomotive returns from Tyseley.

Llangollen Railway apprentices Ben & Joe working on re-fitting the platforms. – Photo:- Kevin West

Other work required before the move to Barrow Hill included re-fitting all the Platform plates removed during the Cylinder and Motion Bracket/Girder work and re-fitting the Smokebox and Smoke Deflectors. Project Chief Engineer Kevin West spent 10 days at Llangollen prior to the planned movement date helping with the locomotive re-assembly. Working with large heavy pieces of locomotive instead of pressing buttons on the computer was a nice change.

The final major work required was to lift the chassis back onto the Driving Wheels. This was done using the Llangollen railway 50 ton rail crane to lift the front of the frames and a hired in 30 ton road crane at the back end. The precision and skill of the crane drivers ensured the job was done in less than an hour.

The previous time the chassis had been moved on it Driving Wheels there had not been the Cylinders fitted. This now means there is an additional 7 tons weight at the front of the Frames. Without the Bogie in place underneath this need supporting. Our first thoughts were to strap a 4 wheel works trolley under the front end, but in the end we decided to use one of the former Road/Railer wheel and axle units that Llangollen works use to move un-wheeled chassis around the works. Chris Collins and Arwell Jarvis made up an adaptor that bolted to the Bogie Bolster mountings and the unit was packed to give the correct height.

The Road/Railer axle and wheels fitted to support the Unknown Warrior's front end.. – Photo:- Kevin West

Once the locomotive had been wheeled it had the impression of a strange 2-6-0 Patriot with very small leading wheels. During shunting the locomotive for loading it ran surprisingly well, rewarding the effort in making the unit.

Llangollen Railway CME Dave Owen supervising lifting the locomotive back onto its Driving Wheels.. – Photo:- Kevin West

The locomotive was due to move to Barrow Hill on Friday 18th September, but after problems with the road transporter the locomotive was loaded on Monday 21st and delivered to Barrow Hill at lunchtime on Tuesday 22nd.

The Unknown Warrior is shunted onto the turntable after arrival at Barrow Hill.. – Photo:- Kevin West

The Unknown Warrior on display at Barrow Hill with Ivatt class 4 2-6-0 43106 on the turntable..

The project sales team in action at Barrow Hill. From left, Neil Kinsey, Karen Kinsey, Mike Dunn, Gavin Shell, Neil Collinson and John Hastings-Thompson. – Photo:- Kevin West

After the Barrow Hill 65 Gala over the weekend on 25th – 27th September the locomotive was once again travelling on the M1 and M42 on it’s way to Tyseley Locomotive Works for fitment of the Bogie and Cylinder & Valve Liners.

Work is also progressing on the drawings for the Drain Cock operation gear and Lubricator Drivesystems. The Drain Cock Gear alone totals 168 individual components.

The four leading Sandboxes were delivered to Llangollen on 10th September and have now been painted ready for fitting to the chassis.

The Sandboxes painted ready to fit to the chassis.. – Photo:- Kevin West

We have taken delivery of copies of the 100 drawings found in the archives of the National Railway Museum, York and the 55 drawings found in the North British Locomotive Co drawing archives, held at Glasgow University from the 50 Royal Scot class locomotives built by NBL. These drawings are either original Patriot drawings or from related locomotives that can be used for the build of The Unknown Warrior.

Brake System and Lubrication System

Refurbishment of the Locomotive & Tender Brake Cylinders from 8F 48518 continues at Harco Engineering.

Design work continues for the lubrication system. The mechanical Lubricator under overhaul at the Great Central Railway, Loughborough is progressing well. The replacement body casting is being sourced with the pattern taken for refurbishment. We have also been made aware of an existing body and lid. This is being check to see if it is suitable.

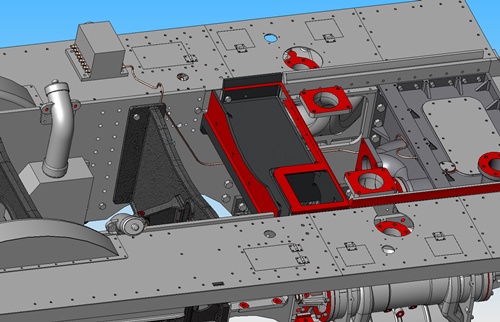

CAD image of lubrication pipe runs – Photo:- Kevin West

Design work for the lubrication pipework runs, fittings and clips continues.

Quotations to machine the Brake Hangers have been obtained and the castings will be moved to Llangollen Engineering in the next week.

We now have the drawings for the Royal Scot class to compare with the details taken from Jubilee Bahamas. Once this is complete the data can be sent out for quotation to get the parts manufactured.

Pistons, Valves and Motion

The Slide Bar Bolts have been completed and delivered to Llangollen.

Detail discussions have continued with Tyseley Locomotive Works with regard to the fitting of the Valve & Cylinder Liners. The castings have been delivered ready for machining. Detail drawings have been completed and passed on to the machining company.

Castings for the Pistons have been ordered and will be delivered to Tyseley once cast.

An order for Tyseley to supply completed Piston and Valve assemblies has been raised. These include finished Pistons, Piston Rings and Piston Rods and Valve Heads, Rings and Rods.

Drawings for the Gland and Stuffing Box parts for the Piston Rods and Valve Rods are in progress to enable manufacture.

The Slide Bar Bolts have been completed and delivered to Llangollen.

Llangollen Railway Engineering are also progressing the manufacture of the Coupling Rod Bushes and Brasses.

Quotations for machining the recently cast Expansion Links are being obtained.

The Unknown Warrior was on display at the Tyseley Works Open weekend at the end of October with work visible in preparation for the fitting of the Cylinder & Valve Liners. The locomotive was decorated with poppies and also the nameplates from Private W Wood VC & Private E Sykes VC.

The Unknown Warrior on display at the Tyseley Open Day 25th October. The Cylinder Covers have been removed in preparation for fitting the liners. Photo – Kevin West

Bogie

The new Bogie Wheelset had its tyres fitted at South Devon Railway Engineering in mid September and was delivered to Tyseley. The trye back to backs have been machined and the final work required is profiling of the treads on both the new wheelset and the wheelset from 48518. This will be done at the London Midland depot next door to Tyseley Locomotive Works.

Assembly of the bogie continues apace at Tyseley Locomotives Works. The bronze bearer pads and the centre bearing were causing issues from Tyseley usual supplier, so we contacted our casting supplier, sent the drawings and cad data, had patterns made and castings supplied to Tyseley within 10 days. These have now been machined and the centre bearing has been pressed into position. The Bearer Pads are ready for fitting.

The Side Control Springs and Beams are due to be fitted this week.

The Bogie Frame Assembly under assembly at Tyseley Locomotive Works. Photo – Kevin West

Final machining of the Axleboxes for the new wheelset is complete and ready for whitemetaling.

The Bogie is due for completion in mid November for fitting to the locomotive chassis.

Boiler

Work continues on the forming blocks for the outer firebox Steel Flanged plates at Tyseley Locomotive Works. The Doorplate block has been cast.

An order for the Outer Wrapper sheets has been raised. Once delivered all the big pieces for the boiler will be to hand or in progress.

At LNWR Crewe, the Inner Firebox Crown and side sheets have been prepared for welding prior to a start being made on assembling the Inner Firebox.

The 2 barrel rings are ready to be riveted together when there is capacity in the works. The Foundation Ring components are ready to be sent away for machining before welding in the side sections.

LNWR Heritage have agreed the completed boiler will be ready for delivery in December 2016.

Tender

Work on the refurbishment on the Tender Frames continues at Rowlescourt Engineering.

Final welding of the new front sections of the outer frames is due to be completed in the next couple of weeks. The new welded dragboxes for both front and back have been assembled and wait machining before they are installed in the frame assembly. This machining has been waiting a slot in Rowlescourt’s machine shop around the companies commercial work programme. As the machine shop has been fully occupied recently we are now looking to send these parts out for machining.

Rowlescourt have committed to complete the chassis repair by the end of the year, if not before. The chassis will be returned to Llangollen as soon as possible to allow the Drag Boxes and outer flanges to be riveted in place.

Design work on the new tank which will be of welded construction with dummy rivets is continuing taking into consideration the requirements for new main line running regulations.

The repair of two of the Tender Axleboxes damaged at Barry scrapyard has been completed and they are now back at Llangollen.

During their time in, the tenders were subjected to removal of the bronze bearings. This was sometimes achieved by smashing off the outer Axlebox Cover with a sledgehammer, rather than unbolting it. Two of the axleboxes we have were subjected to this and sustained damage in the process. One had just lost the ears that the fixing bolt was fitted to, but the other had lost a complete section from the base. These castings have now been restored by specialist Cast Iron welding by Shilton Cast Iron & Welding, of Hinkley.

Bogie Axleboxs at Llangollen. Photo – Kevin West

The Tender Wheelsets are at Llangollen. The welding repairs have been completed to fill the voids in the castings. Painting of the wheelsets is now underway. The journals and Tyre profiles were restored at Tyseley Locomotive works in 2012.

Tender Wheelsets being welded at Llangollen. Photo – Kevin West

Future work planning

Following fitting of the Cylinder & Valve Liners and the Bogie assembly at Tyseley Locomotive Works, the locomotive will return to Llangollen. This is now expected to take place towards the end of November.

Once back at Llangollen work will continue on setting up the Inner Slidebars.

A start will also be made on the lubrication pipework.