HELP US GET MOVING BY JOINING THE ‘5551 CLUB’.

FUNDS RAISED FROM THIS INITIATIVE WILL ENABLE US TO COMPLETE MAJOR WORK ON THE MOTION.

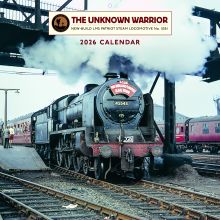

AVAILABLE NOW!

Upcoming events

-

08/11/2025 - 10:00 to 09/11/2025 - 16:00

-

15/11/2025 - 00:00 to 16/11/2025 - 23:45

-

27/11/2025 - 19:30 to 22:00

Search

Latest news

Latest engineering report

OUT NOW

The second volume of Pete Sikes's fabulous pictorial record of the LMS Patriot Class. Featuring multiple photographs of each of the class from No 45526 to 45551 in their original form. (Over 100 images in total)

This book is a fine companion to Volume 1

ISBN 978-1-9995818-0-0

Published by: LMS-Patriot Company Ltd., Civic Centre, Riverside, Stafford, ST16 3AQ

Was £18.95 + £4.00 P+P

Now £10.00 + £4.00 P&P

Price: £14.00